Imagine the labyrinthine complexity of industrial settings, reminiscent of Daedalus’ mythical creations. When it comes to lighting these environments, you need reliable solutions that withstand harsh conditions and ensure safety. Industrial lighting cables are designed to meet these demands, offering durability and energy efficiency. But how do these cables contribute to operational efficiency, and what makes them indispensable in warehouses and manufacturing plants? Understanding the key features and types of these cables could transform the way you approach industrial lighting solutions.

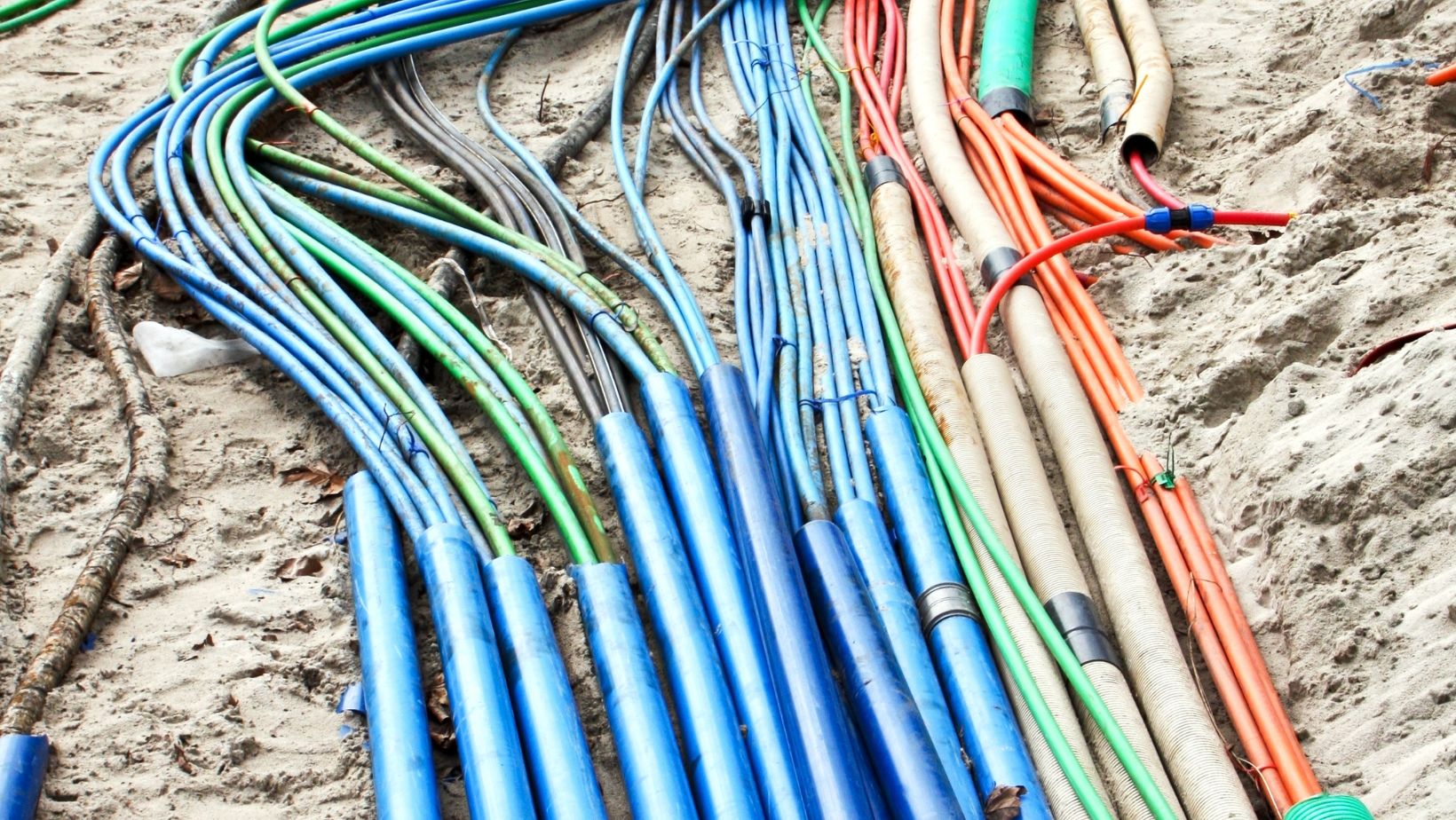

Types of Industrial Lighting Cables

When selecting industrial lighting cable, it’s essential to understand the different types available to ensure optimal performance and safety.

One of the key types is fiber optics. Fiber optic cables are renowned for their ability to transmit light over long distances with minimal signal loss. They’re ideal for environments requiring precise, high-intensity lighting. The core of these cables is made from glass or plastic fibers, which are incredibly effective at guiding light. Their application is particularly advantageous in hazardous or remote areas where electrical interference could be a concern.

Another important type involves cables with robust cable shielding. This shielding is crucial in industrial settings to protect against electromagnetic interference (EMI) and radio frequency interference (RFI). Shielding ensures that the cable’s signal integrity is maintained, preventing disruptions that can compromise lighting performance. The shielding is typically constructed from materials like aluminum or copper, which provide a conductive barrier around the core conductors.

Both fiber optics and shielded cables have unique properties that make them suitable for specific industrial applications. By understanding these types, you can make informed decisions that ensure both safety and efficiency in your industrial lighting projects.

Key Features of Industrial Lighting Cables

Understanding the key features of industrial lighting cables is crucial for ensuring reliable performance and safety in demanding environments.

First and foremost, these cables undergo rigorous durability testing to withstand harsh conditions, including extreme temperatures, moisture, and mechanical stress. This ensures that they maintain functionality and longevity, reducing the risk of unexpected failures.

Another essential feature is compliance with stringent safety standards. Industrial lighting cables must meet specific criteria to prevent electrical hazards, such as short circuits and fires. These standards include proper insulation, grounding, and resistance to chemical corrosion. By adhering to these safety regulations, you ensure the well-being of personnel and the integrity of your operations.

Additionally, flexibility and ease of installation are vital characteristics. High-quality industrial lighting cables are designed to be easily routed through complex environments without compromising performance. This flexibility not only simplifies installation but also allows for efficient maintenance and upgrades.

Applications in Warehouses and Manufacturing Plants

Industrial lighting cables play a critical role in ensuring efficient and safe operations within warehouses and manufacturing plants. You need to adhere to stringent safety regulations, and the right lighting cables help to achieve that. By selecting high-quality cables, you reduce the risk of electrical faults, which can lead to hazardous conditions. For instance, proper insulation and durable materials in these cables prevent short circuits and ensure compliance with safety standards.

Energy efficiency is another crucial factor. In large spaces like warehouses and manufacturing plants, lighting accounts for a significant portion of energy consumption. Using energy-efficient lighting cables can substantially lower your energy bills. These cables are designed to handle high loads with minimal energy loss, which translates to better performance and sustainability.

Furthermore, industrial lighting cables support various lighting technologies such as LED and fluorescent, which are known for their energy efficiency and longevity. By integrating these cables, you can ensure uniform lighting across vast areas, enhancing visibility and reducing the likelihood of accidents. Accurate and consistent lighting not only boosts productivity but also maintains a safe working environment.

Benefits of Using Industrial Lighting Cables

High-quality industrial lighting cables offer numerous advantages that enhance both operational efficiency and safety in industrial settings. One of the primary benefits is energy efficiency. By using advanced materials and technologies, these cables reduce energy loss during transmission, ensuring that more power reaches the lighting fixtures. This improved energy efficiency translates directly into lower energy consumption, promoting cost savings over time.

Moreover, industrial lighting cables are designed to withstand harsh environmental conditions, such as extreme temperatures, moisture, and chemical exposure. This durability minimizes the risk of cable failure, thereby reducing maintenance costs and downtime. With fewer interruptions, your operations can run more smoothly and efficiently.

Safety is another critical benefit. High-quality cables often come with enhanced insulation and protective coatings, reducing the risk of electrical hazards like short circuits and fires. This ensures a safer working environment for your employees, which can also lead to lower insurance premiums and liability costs.

Choosing the Right Industrial Lighting Cable

Selecting the right industrial lighting cable requires a thorough analysis of your specific operational needs and environmental conditions. To begin with, assess the voltage and current requirements of your lighting system. Different cables support varying electrical loads, so matching these specifications ensures optimal performance and safety.

Next, consider the environmental factors. Will the cables be exposed to extreme temperatures, moisture, or chemicals? Choose materials that resist these conditions to prevent degradation over time. For example, PVC-insulated cables offer good resistance to moisture and chemicals, while silicone-insulated cables handle high temperatures better.

Effective installation techniques also play a critical role. Ensure that the cables are properly routed and secured to avoid physical damage and reduce the risk of electrical faults. Utilize conduit systems or cable trays where necessary to provide additional protection and organization.

Once installed, regular maintenance is key to prolonging the cable’s life. Periodically inspect the cables for signs of wear, corrosion, or damage. Implementing these maintenance tips can help you spot issues early and mitigate potential hazards, ensuring a reliable lighting system.

Conclusion

So, you’ve navigated the labyrinth of industrial lighting cables. It’s clear: you need cables that laugh in the face of harsh conditions, sip energy like a fine wine, and make maintenance a distant memory.

Don’t settle for anything less. Your warehouses and manufacturing plants deserve the best—because who doesn’t love spending more time fixing lights, right?

Embrace the brilliance of industrial lighting cables and watch your operational efficiency soar.